Dr. Jonathon Anderson and Dr. Kazem Fayazbakhsh present talks on design and implementation solutions offered by large-scale 3D printing in the fields of architecture and aerospace engineering.

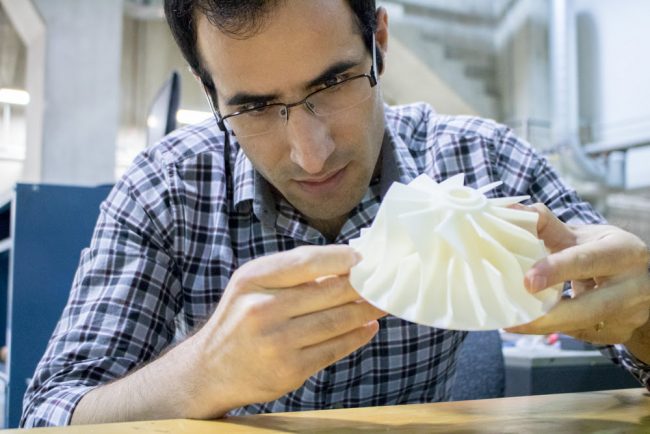

Dr. Kazem Fayazbakhsh,

Assistant Professor, FEAS

Fused Filament Fabrication (FFF) is one of the most popular processes of 3D printing and offers flexibility in manufacturing with a wide range of materials. Commercial desktop FFF 3D printers are cost effective and do not require specific power or installation requirements. Nonetheless, most parts in industry are larger than the build volume of most desktop 3D printers. To help Canadian industry adopt 3D printing, investigation of full-scale components out of high-performance materials is required. In the Facility for Research on Aerospace Materials and Engineered Structures (FRAMES), robotic 3D printing with a 20 in × 20 in build plate is developed. A laser line scanner is also mounted on the robot to inspect parts for defects during printing. Research outcomes in this field will extend the use of 3D printed parts in industrial applications.

Jonathon Anderson,

Assistant Professor, FCAD

On a global scale, cross-disciplinary research to leverage the full potential of digital fabrications and applications of robotics are at the forefront of architectural design.

This presentation will introduce the hardware and software control of a KUKA KR AGILUS industrial robot and the printing process through algorithmic designs. Several projects will be presented to show how the use of a robotic arm with custom engineered end effectors (spool fed and pellet fed extruders) have the ability to export and realize the architectural potentials of robotic extrusion beyond traditional addictive fabrication processes. These digital fabrication systems are applied with traditional design methods to investigate computational craft approaches to designed objects, systems, surfaces, and interiors. Building on the principles of computational craft, robotic fabrication seeks to build on recent advancements by examining the ways in which robotic arms have come to be seen as transcending their traditional role as performers of the monotonous tasks of mass manufacturing pipelines (Gramazio & Kohler, 2008) and instead be viewed as part of the toolset available for the production of crafted and unique work.

Wednesday, April 3, 2019

5-7PM

Collaboratory, Library 3rd Floor (LIB387)

Refreshments provided

Please RSVP by April 2, 12PM